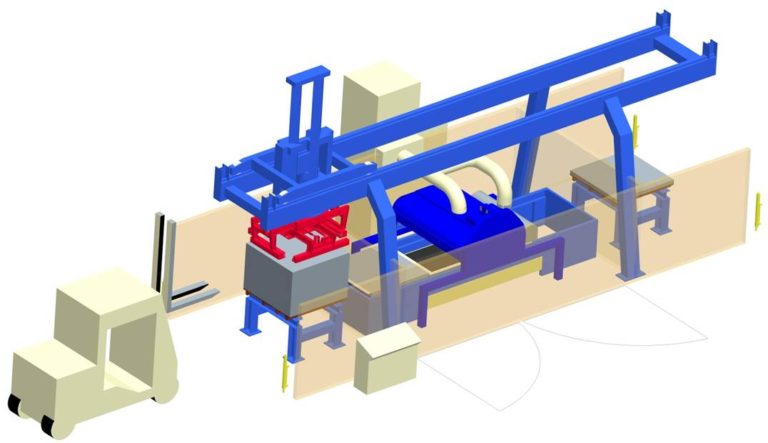

Product refinement

MAKE SOMETHING SPECIAL

Refinement plays an increasingly important role in the field of concrete goods production. A central theme is the artificial aging of the stones. Coloured accents and coatings set trends.

We see ourselves as your development partner in the expansion of your portfolio when it comes to product refinement, as well. Ask us about custom solutions for your product idea.