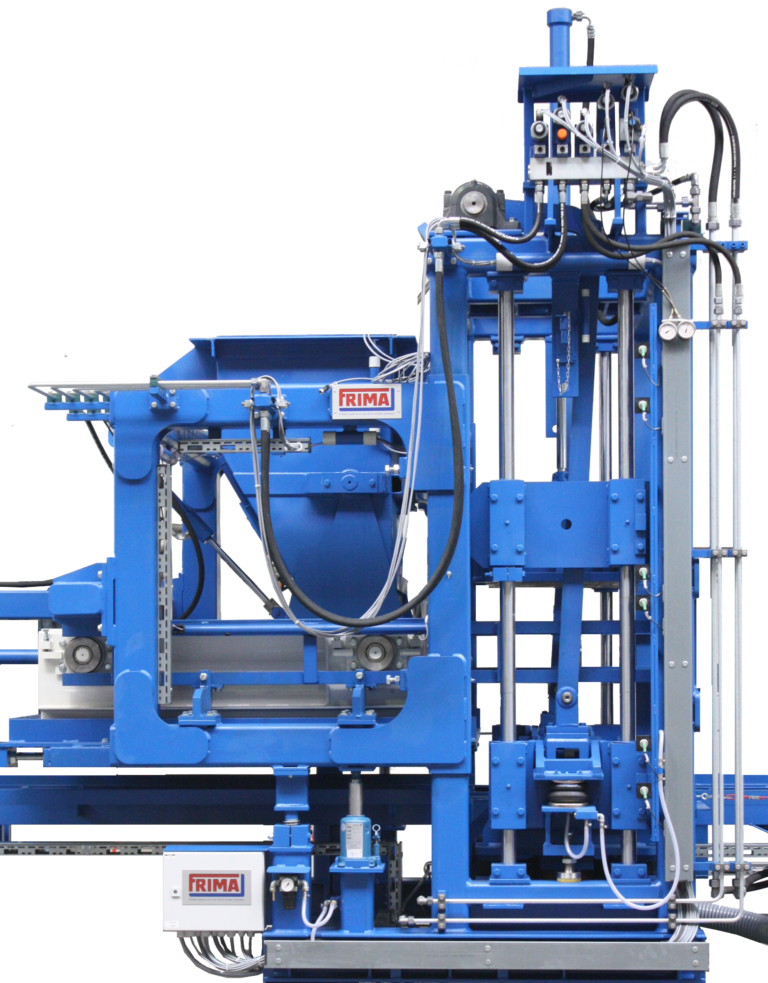

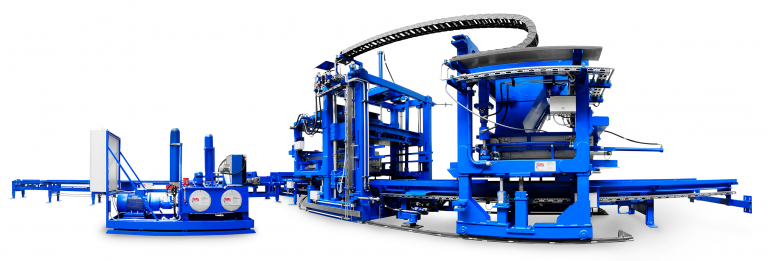

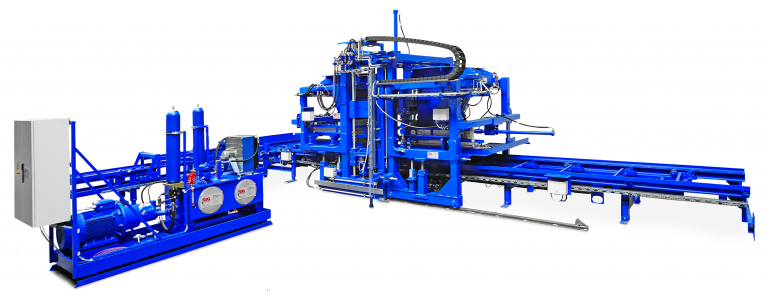

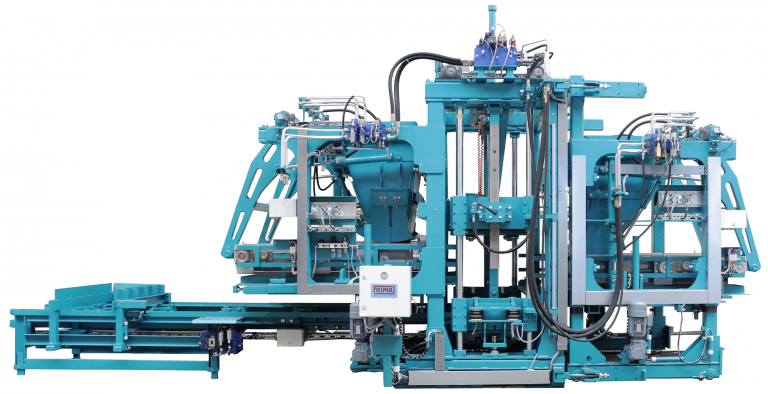

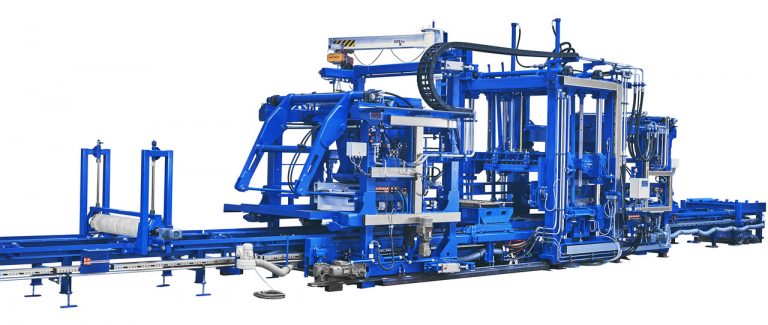

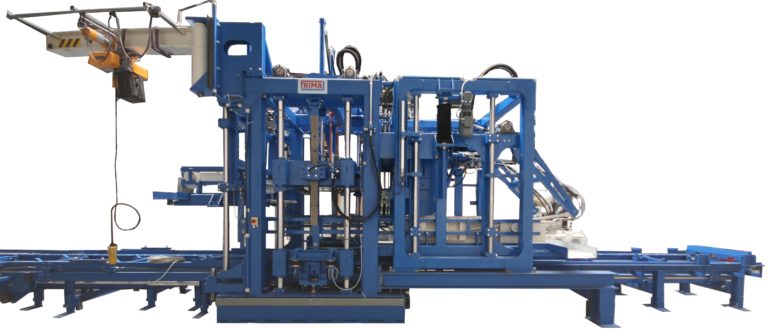

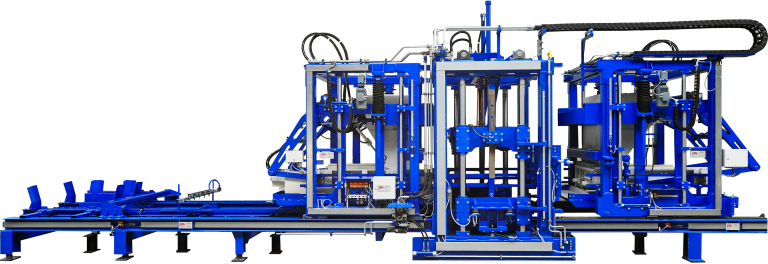

Custom concrete block machines

As a full-service supplier, we offer you a comprehensive product range of concrete block machines. The models cover various customer requirements and leave plenty of scope for individual adjustments.

As a core element of the system, concrete block machines from FRIMA can be integrated into a wide variety of system layouts and combined with a variety of other systems.

YOUR BENEFITS

You only have one responsible project partner. All parts of the system are perfectly tailored to one another.

The comprehensive FRIMA product range offers individual solutions for all your needs. But we also see ourselves as a development partner who works with you to design, manufacture and accompany your solution right through to commissioning.